Whether the bolt thread is completely qualified, buttered and wrapped in plastic film

When it comes to the bolt level difference (±3mm, 0), it's essential to check whether the bolt thread is intact. After passing the inspection, the bolts should be coated with grease, wrapped in plastic film, and finally covered with a plastic sleeve. Both the sleeve method and the bracket method may encounter situations where the bolt or bolt bracket conflicts with the position of the rib or the ground beam. In this conflict, the accuracy of the bolt positioning becomes the primary issue. Adjusting the position of the reinforcement bars can only be used as a means to ensure the precision of the bolt placement.

During the detailed design of the steel structure and the confirmation of that design, it's crucial to take into account the inevitable conflicts between bolts and reinforcement bars. When the anchoring length of the bolt is sufficient, it's preferable not to install the bottom anchor plate (as it may easily collide with the reinforcement bar, affecting its position). The Boshan water pump leaves some space for structural design, and if needed, the number and spacing of the reinforcement bars can be adjusted accordingly. Both the plate method and the bracket method are process control techniques aimed at ensuring the accurate placement of embedded bolts, which is a critical part of steel structure engineering.

Through the practical application of this project, both methods have their own advantages. As long as the above-mentioned procedures are strictly followed, the installation accuracy can be ensured. These methods are simple to implement and offer high precision, making them ideal for steel column installation and ensuring the stability of the steel columns. With careful execution, these approaches provide reliable results and contribute significantly to the overall quality of the construction work.

Optical Flats mirrors are ideal for a variety of applications including interferometry, imaging systems, laser applications, optical path folding, and autocollimation. These mirrors are available in a variety of coating and substrate options, along with surface flatness options of λ/10 and λ/20. Fused Silica, is optically clear and features excellent resistance to abrasion and high durability, making it the best choice for applications in harsh environments.

The mirrors are available in circular, square, and rectangular dimensions. Rectangular first surface mirrors are ideal for applications requiring the mirror to be mounted at 45° in order to produce a 90° bend in the light path.

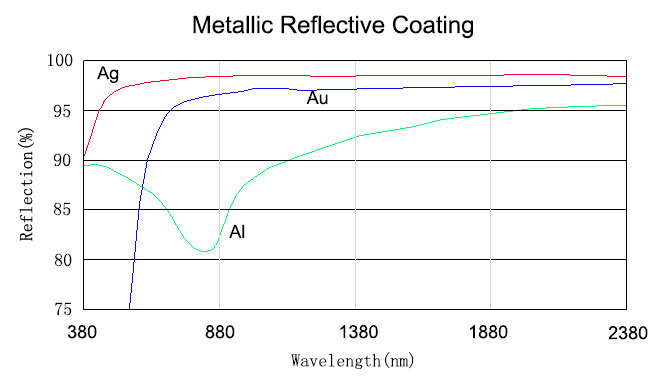

Protected metallic coatings provide a moderate level of reflection over a very broad spectral range and are widely used as mirrors. These coatings are protected by a thin layer of dielectric material in order to make them durable. Enhanced metallic coatings provide greater reflection across the operating band width. These coatings are enhanced by adding a multilayer dielectric stack. Metal coatings will modify the state of polarization of an incident beam of light and are therefore inappropriate for most polarization sensitive applications.

+

Optical Glass Flat Mirror,Optical Glass Protective Flat Mirror,Al Protective Mirror,Aluminium Flat Mirror

China Star Optics Technology Co.,Ltd. , https://www.csoptlens.com